Introduction: The Importance of Safe Borax Decahydrate Handling

Borax decahydrate, a widely used industrial chemical, plays a crucial role in multiple sectors including detergents, ceramics, and glass manufacturing. Despite its broad application, improper handling or storage can lead to serious safety risks and product degradation. This makes it essential for businesses to adopt a proactive safety strategy tailored to this compound. Proper protocols not only minimize accidents but also enhance operational efficiency.

Industrial users across India have started prioritizing chemical safety regulations, especially under ISO and OSHA standards. In such a framework, borax decahydrate demands particular attention due to its hygroscopic nature and potential health effects. Creating an informed workforce that understands these risks is the foundation of safe chemical management.

Training employees on safe handling and reinforcing habits like using personal protective equipment (PPE) helps prevent exposure-related illnesses and costly incidents. Furthermore, investing in well-structured storage facilities protects the product’s chemical stability, ensuring consistent quality in applications.

For businesses sourcing borax decahydrate, ensuring the material arrives and remains in optimal condition is essential. Suppliers like Chemtradeasia India offer detailed MSDS and TDS documentation to help clients manage safety throughout the supply chain.

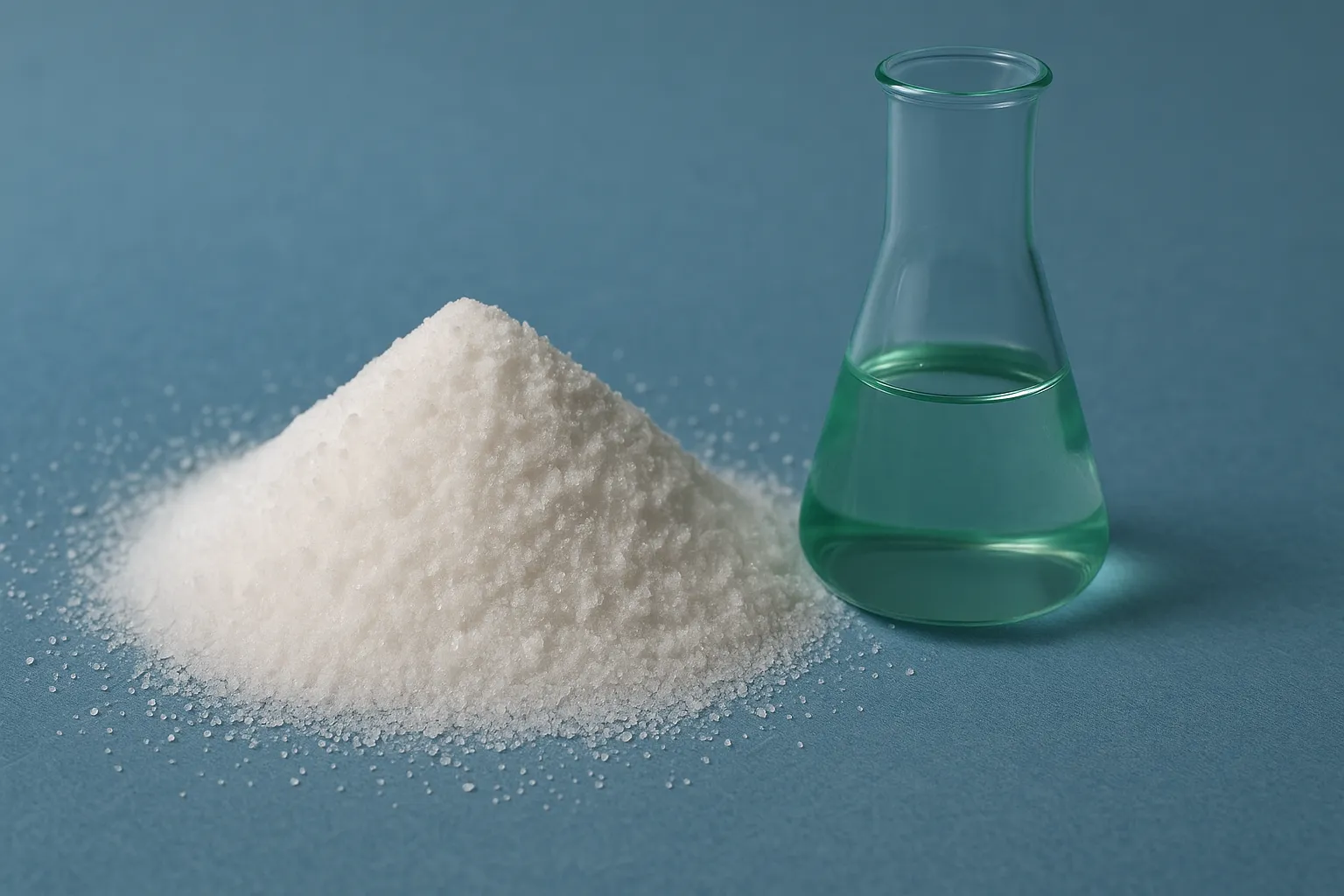

Understanding the Chemical Nature of Borax Decahydrate

Borax decahydrate (Na₂B₄O₇·10H₂O) is a white, crystalline compound composed of sodium, boron, oxygen, and water molecules. It is commonly used in its granular form and is prized for its buffering and cleaning capabilities. However, due to its water content, it is highly sensitive to humidity and temperature changes, which makes it vital to understand its chemistry before handling.

When exposed to heat or prolonged air contact, borax decahydrate gradually loses water and transforms into borax pentahydrate or even anhydrous borax. This affects its chemical behavior, solubility, and performance in applications like glassmaking or metallurgy. Hence, the handling environment must be carefully controlled to preserve product integrity.

Additionally, borax is classified as a mild irritant to the eyes and skin. Inhalation of fine particles may cause respiratory discomfort or irritation, especially for untrained workers in poorly ventilated environments. This underlines the necessity for strict airborne particle control and proper labeling practices in workplaces.

Buyers interested in long-term bulk procurement should always choose trusted suppliers who maintain high packaging standards. Chemtradeasia offers technical-grade granular borax decahydrate sourced from Turkey, ensuring consistent quality across batches, aiding clients in maintaining safe and reliable operations.

Personal Protective Equipment (PPE) Guidelines for Workers

Proper use of PPE is a frontline defense in minimizing worker exposure to borax decahydrate. Employers must ensure all personnel handling this chemical wear safety goggles, chemical-resistant gloves, and dust masks or respirators. These items help prevent direct skin contact and inhalation of fine particulate matter during loading, mixing, or weighing operations.

Employers should also provide work uniforms or aprons that can be easily decontaminated. Regular laundering of clothing worn during borax handling prevents chemical accumulation, reducing the risk of secondary exposure. Eye wash stations and emergency showers must be placed within easy access in case of accidental splashes or contact.

Training programs are critical to make sure PPE is used correctly and consistently. For instance, respirators must be fitted properly to be effective, and workers should be trained on when to replace or clean their equipment. According to the Occupational Safety and Health Administration (OSHA), chemical-specific PPE protocols must be established and periodically reviewed.

Safety culture is not just about equipment but also mindset. By sourcing high-quality borax from suppliers who offer full regulatory compliance and technical guidance—like Chemtradeasia India—companies reinforce their commitment to workplace safety and chemical handling excellence.

Best Storage Practices for Borax Decahydrate

Maintaining borax decahydrate in a stable, effective form requires controlled storage conditions. The compound should be stored in a cool, dry, and well-ventilated area away from sources of moisture. Relative humidity should be kept below 50% to prevent clumping and degradation caused by water absorption.

Storage containers must be tightly sealed, preferably made of polyethylene or similar moisture-resistant materials. Opened bags or drums should be used promptly or resealed with industrial-grade closures to avoid air contact. Pallet storage should elevate containers off the ground to prevent water damage during warehouse cleaning or floods.

Temperature control is equally vital. While borax decahydrate is stable under typical ambient conditions, prolonged exposure to heat can lead to water loss and change in chemical composition. Avoiding direct sunlight and placing containers in shaded or air-conditioned warehouses ensures prolonged shelf-life.

Large-scale buyers who maintain warehouse inventories must evaluate supplier packaging standards. Chemtradeasia India supplies high-grade borax in moisture-resistant packaging, helping clients maintain chemical quality even in India’s humid climate.

Emergency Response and Spill Management

In the event of a borax spill, quick and structured action is essential. Workers should immediately isolate the area and don appropriate PPE before attempting cleanup. Small spills can be swept or vacuumed using equipment fitted with HEPA filters to prevent dust release. The collected material should then be disposed of according to local hazardous waste guidelines.

For large spills, it's advisable to use industrial vacuum systems and alert the onsite safety officer. Borax is not flammable, but it should not be washed down into drains as it may affect aquatic environments. As per India’s Environment Protection Rules, disposal procedures must comply with CPCB and local pollution control board guidelines.

Emergency procedures should also include exposure response. For eye contact, flush with water for at least 15 minutes and seek medical attention. If inhaled in large quantities, move the affected individual to fresh air and consult a physician. Documenting every incident and conducting post-incident reviews are essential to preventing recurrence.

Workplaces that procure borax decahydrate in bulk quantities must develop a written emergency response plan. By partnering with chemical suppliers like Chemtradeasia, companies gain access to material safety data sheets (MSDS), emergency consultation, and logistics support in case of contamination or accidents.

Conclusion: Safer Operations with Smart Practices

Borax decahydrate is a valuable industrial material when handled correctly. Ensuring the right handling, storage, and emergency protocols can significantly reduce safety risks and preserve the product’s chemical quality. From understanding its hygroscopic nature to enforcing PPE compliance, businesses must treat borax as more than just a commodity.

A comprehensive chemical safety approach not only fulfills regulatory requirements but also promotes operational sustainability. This reduces employee turnover due to health concerns and decreases downtime caused by product spoilage or regulatory fines. Safety, after all, is a business advantage.

Choosing the right supplier also plays a major role. With global sourcing and localized support, Chemtradeasia India ensures clients receive premium quality borax along with handling documentation and expert consultation, contributing to safer industrial environments.

For consultation, bulk quotes, or MSDS access, visit the Chemtradeasia India contact page and speak directly with our team. Your safety is our priority—partner with a supplier that understands industrial needs inside out.

Leave a Comment